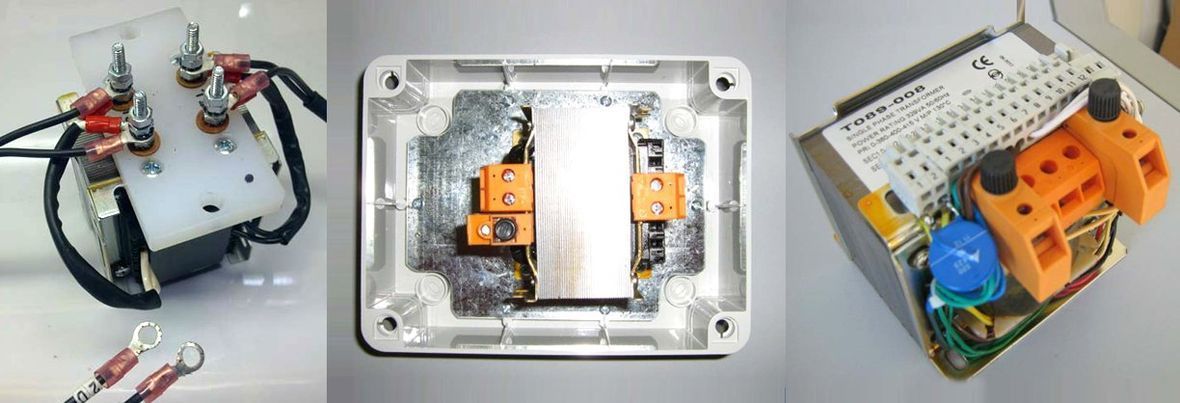

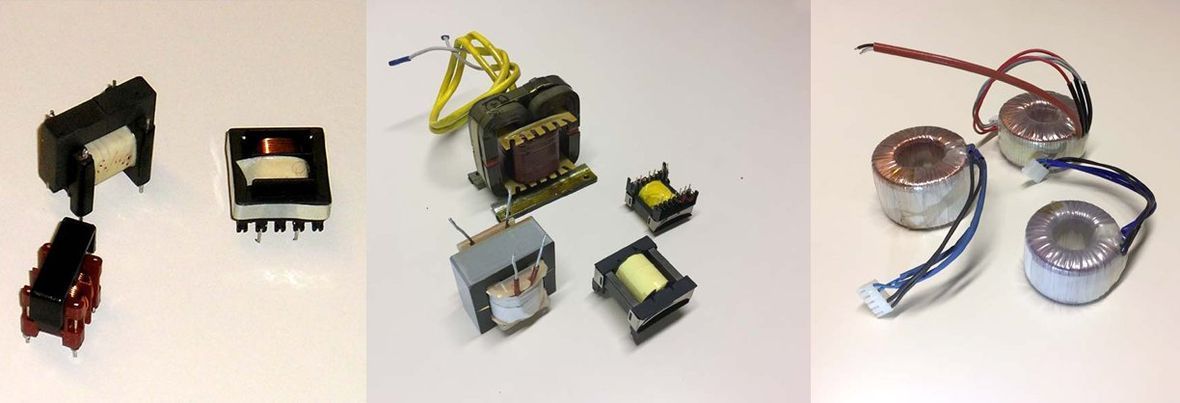

Single-phase transformers

Single-phase transformers are electrical transformers that operate on alternating current and are used to transfer electrical power from one voltage level to another. Transformers consist of a magnetic core and at least two electrical windings.

The windings are classified according to the number of turns, the high-voltage (HV) one having the highest number of turns

(smaller cross-sectional area) and the low-voltage (LV) one with fewer turns (smaller cross-sectional area). Single-phase autotransformers, unlike single-phase transformers, have only one winding and do not have galvanic separation between the two windings. S.V.T. single-phase transformers and single-phase autotransformers are designed and manufactured using top-quality materials: electrolytic copper conductors in wire and strip and aluminium, insulators with high dielectric and thermal properties (class F and H) and thermal properties (class F and H), impregnation with paint or epoxy resins and extremely robust and safe mechanical support parts suitable for any installation requirement.

S.V.T. single-phase transformers and autotransformers can be supplied complete with accessories

and customised wiring, based on the end customer's specific requirements.

On request, a metal box for various levels of machine protection can be supplied. In addition, a protection shield can be applied between the primary and secondary windings to ensure a higher degree of insulation and protection against overheating, which can be either automatic or manual, depending on the application required.

The quality of S.V.T.'s single-phase transformers and autotransformers is verified on several levels: each phase

of manufacturing is checked, from the initial winding

to the final testing of the transformer itself.

Each transformer after production is 100% tested. This certifies the electromagnetic performance and the guaranteed safety level of each transformer produced. The pre-testing as well as the final inspectionis performed in accordance with the CEI EN 61558 - CEI 96.7 - 96.8 - CE standards, according to

the type of transformer and its use. The careful control of production processes and customised testing

with dedicated and specially designed equipment guarantees S.V.T. electrical transformers maximum reliability.

It should also be noted that S.V.T. single-phase transformers and single-phase autotransformers are manufactured with automatic machines in order to guarantee maximum reliability

and repeatability in electrical tolerance parameters.

S.V.T. designs and develops different types of single-phase transformers and single-phase autotransformers designed

and customised according to the end customer's needs, maximising performance and preventing any problems. S.V.T., single-phase transformers and single-phase autotransformers cover a wide range of applications with dimensional and technical characteristics ranging from standard to the most complex customisations.

S.V.T. supports its customers from the design

and customisation of single-phase electrical transformers

and single-phase autotransformers to guarantee maximum results in terms of economic and technical performance.

S.V.T. electrical transformers find application in a variety of sectors such as the quadristic sector, home automation, and more generally in all those applications where

voltage variation is required with respect to the voltage with which the transformer itself is supplied. Precise and

and binding tests ensure a high degree of safety and reliability of every single transformer produced, in compliance with current national and international regulations.

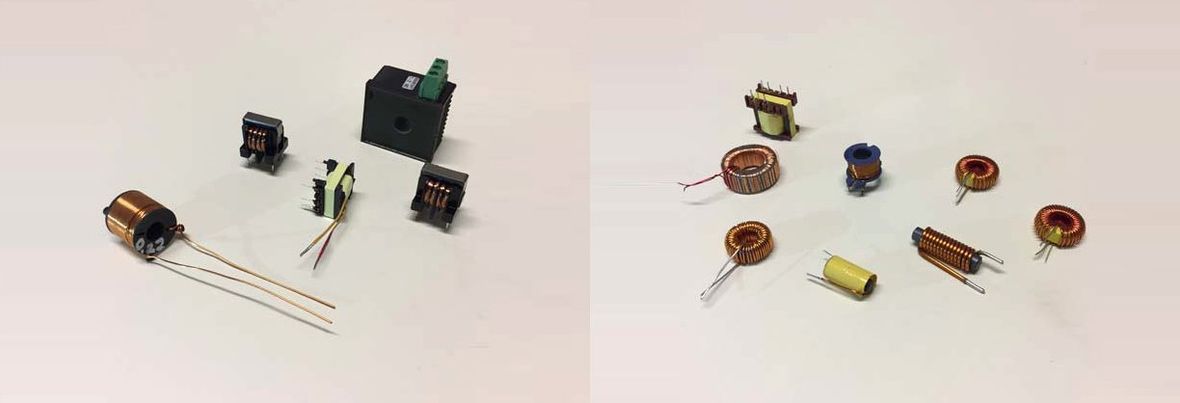

Transformers for printed circuit boards

PCB transformers are electrical transformers that operate on alternating current and are used to transfer electrical power from one voltage level to another. Transformers consist of a magnetic core and at least two electrical windings.

The windings are classified according to the number of turns, the high voltage (HV) winding having a higher number of turns (smaller cross-sectional area) and the low voltage (LV) winding having fewer turns (smaller cross-sectional area).

PCB transformers, whether painted transformers or resinated transformers, are used in all electrical and electronic boards where there is a need to vary the input voltage with respect to the output voltage, galvanically separating the circuit.

Painted transformers are impregnated with special self-extinguishing paint to protect them both mechanically (from rust, vibrations, etc.) and electrically (the paint acts as an insulator, thereby reinforcing the transformer's insulation).

Resinated transformers are encased in a container with self-extinguishing epoxy resin. The finished transformers have an IP66 degree of protection, which makes them suitable for use in wet environments, or even in contact with water.

These enclosures used for resin-bonded transformers can also have slots for fixing them to the board or switchboard, or the transformers can be supplied with terminals or output leads, or alternatively with an input plug cable and an output cable piece.

On request they can also be equipped with a rail suitable for mounting on DIN OMEGA (DIN RAIL). S.V.T. PCB transformers are designed and manufactured with top quality materials, electrolytic copper wire conductors, insulators with high dielectric and thermal properties (class F and H), extremely sturdy and safe mechanical support parts suitable for any installation requirement.

S.V.T. PCB transformers can be supplied complete with customised accessories and wiring, based on specific customer requirements.

On request, an overheating protection thermal can also be applied to the primary winding, which can be either automatic or manual reset, depending on the application required.

The quality of S.V.T.'s painted transformers and resin-bonded transformers is verified on several levels: every stage of production is checked, from the initial winding to the final testing of the transformer itself. Each transformer after production is 100% tested. In this way, the electromagnetic performance and guaranteed safety level is certified for each transformer produced. The pre-testing as well as the final inspection is carried out in accordance with the applicable CEI EN 61558 - CEI 96.7 - 96.8 - CE standards, depending on the type of transformer and its use.

PCB transformers are electrical transformers which operate on alternating current and are used to transfer electrical power from one voltage level to another. Transformers consist of a magnetic core and at least two electrical windings.

The windings are classified according to the number of turns, the high voltage (HV) winding having a higher number of turns (smaller cross-sectional area) and the low voltage (LV) winding having fewer turns (smaller cross-sectional area).

PCB transformers, whether painted transformers or resinated transformers, are used in all electrical and electronic boards where there is a need to vary the input voltage with respect to the output voltage, galvanically separating the circuit. Painted transformers are impregnated with special self-extinguishing paint to protect them both mechanically (from rust, vibrations, etc.) and electrically (the paint acts as an insulator, thereby reinforcing the transformer's insulation).

Resinated transformers are encased in a container with self-extinguishing epoxy resin. The finished transformers have an IP66 degree of protection, which makes them suitable for use in wet environments, or even in contact with water. These enclosures used for resin-bonded transformers can also have slots for mounting on the board or switchboard, or the transformers can be supplied with terminals or output leads, or alternatively with input plug cable

and a piece of cable at the output.

On request, they can also be equipped with a rail suitable for mounting on a DIN OMEGA (DIN RAIL).

S.V.T. PCB transformers are designed and manufactured with top quality materials, electrolytic copper wire conductors, insulators with high dielectric and thermal properties (class F and H), extremely robust and safe mechanical support parts suitable for any installation requirement. S.V.T. PCB transformers can be supplied complete with customised accessories and wiring, based on the end customer's specific requirements.

On request, an overheating protection thermal can also be applied to the primary winding, which can be either automatic or manual reset, depending on the application required.

The quality of S.V.T.'s painted transformers and resin-bonded transformers is verified on several levels: every stage of production is checked, from the initial winding to the final testing of the transformer itself. Each transformer after production is 100% tested. In this way, the electromagnetic performance and guaranteed safety level is certified for each transformer produced. The pre-testing as well as the final inspection is carried out in accordance with the applicable CEI EN 61558 - CEI 96.7 - 96.8 - CE standards, depending on the type of transformer and its use.

The careful control of production processes and customised testing with dedicated and specially designed equipment guarantees S.V.T. electrical transformers maximum reliability. It should also be noted that S.V.T. electrical transformers are manufactured with automatic machines in order to guarantee maximum reliability and repeatability in electrical tolerance parameters. S.V.T. designs and develops different types of transformers designed and customised according to the end customer's needs, maximising performance and preventing any problems. S.V.T. board transformers cover a wide range of applications with dimensional and technical characteristics ranging from standard to the most complex customisations. S.V.T. supports its customers right from the design and customisation of electrical transformers, so as to be able to guarantee maximum results in terms of economic and technical performance.

S.V.T.'s electrical transformers are used in a variety of sectors such as the switchboard sector, home automation, and more generally in all those applications where voltage variation is required with respect to the voltage with which the transformer itself is supplied. Precise and binding tests ensure a high degree of safety and reliability

of each transformer produced, in compliance with current national and international standards.

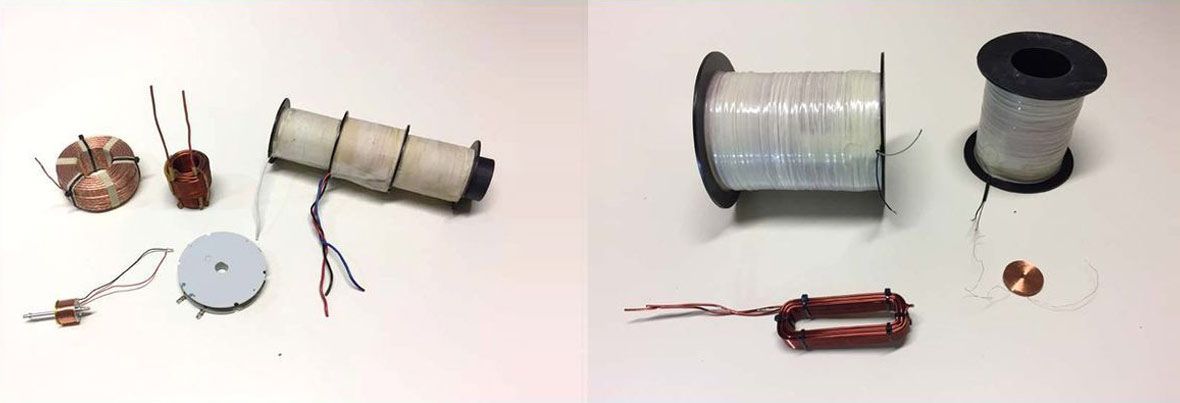

Low-profile transformers

Low-profile transformers are electrical transformers that operate on alternating current and are used to transfer electrical power from one voltage level to another. Transformers consist of a magnetic core and at least two electrical windings. The windings are classified according to the number of turns, the high-voltage (HV) winding having the highest number of turns (smaller cross-section) and the

low-voltage (LV) with a lower number of turns (smaller cross-section). S.V.T. low-profile transformers are designed and manufactured using top quality materials, electrolytic copper wire conductors, insulators with high dielectric and thermal properties (class F and H), extremely sturdy and safe mechanical parts suitable for any installation requirement.

These electrical transformers are designed for safety

safety applications and cover a wide power range.

The main features of the low-profile transformers are small dimensions, high reliability and high efficiency, unique to an optimal degree of insulation between primary and secondary. The standard version of low-profile transformers

low-profile transformers are impregnated with self-extinguishing epoxy resin, class F insulation and a protection class suitable for class II electrical equipment.

On request, an overheating protection thermal can also be applied to the primary winding, which can be either automatic or manual reset, depending on the application required.

The quality of S.V.T. electrical transformers is verified

on several levels: every production step is checked, from the initial winding to the final testing of the transformer itself. Every transformer after production is 100% tested. In this way, the electromagnetic performance and guaranteed safety level is certified for each transformer produced.

Pre-testing as well as final testing is carried out in accordance with the applicable CEI EN 61558-CEI 96.7-96.8-CE standards, depending on the type of transformer and its use

The careful control of production processes and customised testing with dedicated and specially designed equipment guarantees S.V.T. electrical transformers

electrical transformers for maximum reliability.

It should also be noted that S.V.T. electrical transformers are manufactured with automatic machines in order to guarantee maximum reliability and repeatability in electrical tolerance parameters.

S.V.T. designs and develops different types of transformers designed and customised according to the end customer's needs, maximising performance and preventing any type of problem. S.V.T.'s low-profile transformers cover a wide range of applications with dimensional and technical characteristics ranging from standard to the most complex customisations.

S.V.T. supports its customers from the design and customisation of electrical transformers, in order to

to guarantee the best possible result in terms of economic

and technical performance. Precise and binding tests ensure a high degree of safety and reliability of every single transformer produced, in compliance with current national and international standards.